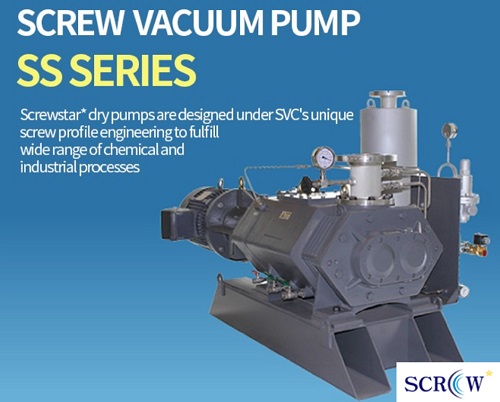

Dry Screw Vacuum Pump Technology & Reliance SVC CO., LTD of Chemistar Series in Korea

SVC was established based on advanced technology and

management philosophy of value creation with customers and SVC is a specialized

company which manufactures the world highest level vacuum pump and vacuum

pumping system.

SVC has been designing, manufacturing and supplying

important process of Dry Screw Vacuum Pump & System, Liquid Ring Vacuum

Pump & System and Steam Ejector system and employees who have over 30 years

of vacuum experience including board of directors have been growing as a true partnership

of the various industries with grafting accumulated pro-cess technologies and

production technologies.

Chemistar Series:

Historically Chemical & Process Industries use steam

ejectors, liquid ring pumps and once-through oil lubricated rotary pumps to meet

their process needs for various level of vacuum condition% which generate waste

water and process effluent disposal. Nowadays in order to be compliant with

restrictive national and international environmental regulations, to reduce

operating cost, to enable easier pro-cess control and maintenance, these

industries have replaced their existing pump-ing units with mechanical

solutions. Ideally pump welcome only gases and vapors but in such dynamic

process environments with various process material% chemi-cal processes often

involve toxic, aggressive and explosive materials, in some worst cases, liquid

and solid carry-over. All protective equipments like filters, frame arresters

and condensers, etc are fitted at both up and downstream of pumps but not

sufficient always to overcome potential problems Dry screw vacuum pump korea

Chemistar s are designed to efficiently pass over the

minimal level of unexpected by-products and/or carry-overs to protect itself and

minimize process down time even though it will be never perfectas mechanical

limitation cannot be completely over-come.

Optional Accessories:

·

Chemical & Process Applications

·

Pre-condenser

·

Inlet Knockout Pot

·

Receiver

·

Isolation Valve

·

Inlet Purge Kit

·

Solvent Flush Kit

·

Steam Flush Kit

·

Inlet Filter

·

Flame Arresters

·

Exhaust Silencer

·

Exhaust Pressure Switch

·

Exhaust Gas Temperature Transmitter

·

Seal Purge Kit -Control Panel -Junction Box

Specification:

·

18.5kW(60Hz) can be used according to process,

please, contact SVC for details.

·

For more information of motor and SS2000,

please, consult with factory.

Comments

Post a Comment