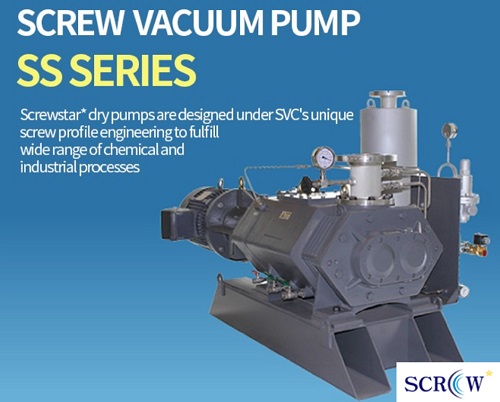

Overview of Dry Screw Vacuum Technology for Diverse Applications Screwstar in Korea

SVC was established based on advanced technology and

management philosophy of value creation with customers and SVC is a specialized

company which manufactures the world highest level vacuum pump and vacuum

pumping system.

SVC has been designing, manufacturing and supplying

important process of Dry Screw Vacuum Pump & System, Liquid Ring Vacuum

Pump & System and Steam Ejector system and employees who have over 30 years

of vacuum experience including board of directors have been growing as a true partnership

of the various industries with grafting accumulated pro-cess technologies and

production technologies.

Screwstar Dry pumps are designed under SVC's unique screw

profile engineering to fulfill wide range of chemical and industrial processes

by rotating a paired screw that efficiently admit gases from inlet into the

pump inside and compress through the screws' swept volume toward the discharge.

The hybrid screw design with engineered combination of vari-able pitches, in

comparison with traditional ones, significantly increases compression

efficiency for faster and smoother pumping but Dry Screw Vacuum Pump

generation for safe pumping, particularly at the discharge,

which comes from the specialty design of unique hydrodynamic spiral jacket

cooling mechanism that results fulfilling ATEX directives. It also

significantly reduces electrical consumptions but with sufficient pumping from

atmo-sphere to its ultimate vacuum. Non-seized rotation of screws without lubricants

between screws and stator can be achieved by precision ma-chining and balanced

assembly of timing gears and bearings that are lubricated but well-sealed from

pumping chamber.

Features:

·

Hybrid Combined Variable Pitch

·

Fast Exhaust Performance

·

10-3 Tor High Vacuum Achievable

·

Applicable for Various Processes

·

Low Vibration, Low Noise

·

Low Discharge Temperature

·

Low Temperature by Hydrodynamic Helix structure

·

Minimizing Power Consumption with Power-saving

Design

·

Improved Durability by Special Coating

·

Minimizing condensation by Hot Pumping

·

Gas Purge Seal application

·

Operating Temperature Control (TCV) and

Prevention of Overheating (TE or TSS)

·

Control of The Cooling Water Consumption

·

Cooling Gas is Not Necessary

·

Minimizing condensation by Using Gas Ballast

·

Improved Durability by Seal Purge, Inlet Purge,

Solvent Flush and Steam Flushing

Comments

Post a Comment