SVC Minimizing Condensation by Special Casing Mechanism of Suction Groove and Discharge Groove

SVC was established based on advanced technology and

management philosophy of value creation with customers and SVC is a specialized

company which manufactures the world highest level vacuum pump and vacuum

pumping system.

SVC has been designing, manufacturing and supplying

important process of Dry Screw Vacuum Pump & System, Liquid Ring Vacuum

Pump & System and Steam Ejector system and employees who have over 30 years

of vacuum experience including board of directors have been growing as a true partnership

of the various industries with grafting accumulated pro-cess technologies and

production technologies.

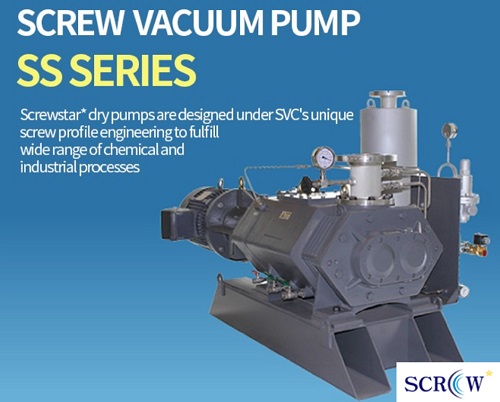

Screwstar Dry pumps are designed under SVC's unique screw

profile engineering to fulfill wide range of chemical and industrial processes

by rotating a paired screw that efficiently admit gases from inlet into the

pump inside and compress through the screws' swept volume toward the discharge.

The hybrid screw design with engineered combination of vari-able pitches, in

comparison with traditional ones, significantly increases compression

efficiency for faster and smoother pumping but

Minimizing Condensation by Special Casing Mechanism

(Patented):

Suction Groove:

To avoid corrosion by minimizing the condensation between

first spiral and second spiral of screw inside of Dry Screw Vacuum Pump. Dry screw vacuum pump

Discharge Groove:

To minimize corrosion and abrasion through discharging

process product smoothly.

Suction & Discharge Groove:

Dust handling ability is supreme thanks to more turbulent

and chaotic motion through design and application of groove.

After 3 years used in Pharma process with acetone, ethanol,

methanol, IPA and etc., the condition is as the shown picture.

This condition is operated within three-year operation in

the same application after applying casing groove.

Enhanced Durability with Special Coating:

Special PEEK Coating (40μm) which has 10 times higher

abrasion resistance than Teflon coating as our standard or Nickel (10μm) +

Special PEEK Coating (30μm) can be applied for strengthening the durability of

coating selectively. Dry screw vacuum Technology

korea

Cooling Mechanism & Hot Water-Cooling Mechanism:

·

Maximize cooling effect by applying Hydrodynamic

Spiral Jacket Cooling Mechanism

·

Hot water (Upto 70℃) can be used for cooling

mechanism for process product which has high melting point to avoid solidifying

inside of pump, discharge smoothly, and increase durability.

Comments

Post a Comment