Overview of Dry Screw Vacuum Pump uses and its Features

SVC was established based on advanced technology and

management philosophy of value creation with customers and SVC is a specialized

company which manufactures the world highest level vacuum pump and vacuum

pumping system.

SVC has been designing, manufacturing and supplying

important process of Dry Screw Vacuum Pump & System, Liquid Ring Vacuum

Pump & System and Steam Ejector system and employees who have over 30 years

of vacuum experience including board of directors have been growing as a true partnership

of the various industries with grafting accumulated pro-cess technologies and

production technologies.

Dry screw vacuum operate work with two screw rotors rotating

in inverse ways. This snares the medium to be siphoned between the chamber and

the screw chambers and transports it to the gas release. The propelled screw

configuration brings about lower electric vitality utilization contrasted with

standard screw structures. It additionally brings about a lower heat heap of

the packed gas. Dry Screw Vacuum Pump

Manufacturer

Cooling can be accomplished through a superior air cooling

technique killing the need of cooling water or backhanded cooling strategy

bringing about uniform temperatures all through the siphon body, disposing of

cold spots and giving a thermally steady water coat. The propelled screw

configuration takes into consideration top tier hydrogen siphoning capacities.

Water cooling can happen in type of both direct water cooling and radiator cooling

with air-cooled heat exchangers

Significant Features:

Advance innovation Double fixing framework for airtight

design. Oil and Water free dry running activity makes clean operation. Suitable

for siphoning dangerous, destructive and condensable gas by Vacuum pumping system supplier extraordinary

material of development No metal to metal contact among screws and Casing

guarantees long siphon life. Relatively low force utilization and low

maintenance. Considerable decrease in siphon down time of vacuum machines. Dry

Pumping appropriate for gas/fume load. Low vitality utilization.

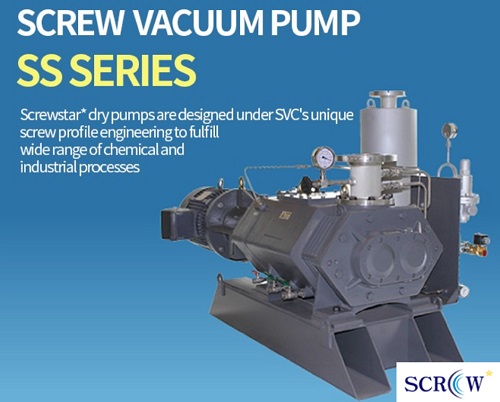

Screw star Dry pumps are designed under SVC's unique screw

profile engineering to fulfill wide range of chemical and industrial processes

by rotating a paired screw that efficiently admit gases from inlet into the

pump inside and compress through the screws' swept volume toward the discharge.

The hybrid screw design with engineered combination of vari-able pitches, in

comparison with traditional ones, significantly increases compression

efficiency for faster and smoother pumping

Comments

Post a Comment