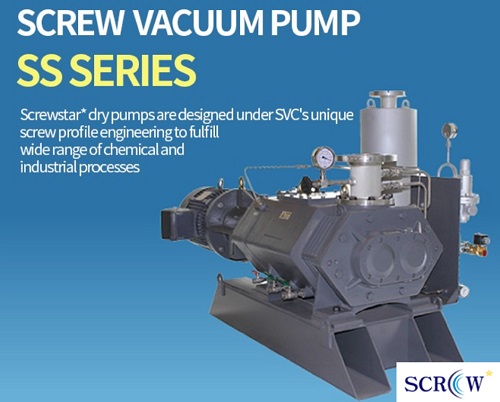

SVC Highlights of Dry Screw Vacuum Pump Korea

SVC was established based on advanced technology and

management philosophy of value creation with customers and SVC is a specialized

company which manufactures the world highest level vacuum pump and vacuum

pumping system.

SVC has been designing, manufacturing and supplying

important process of Dry Screw Vacuum Pump & System, Liquid Ring Vacuum

Pump & System and Steam Ejector system and employees who have over 30 years

of vacuum experience including board of directors have been growing as a true partnership

of the various industries with grafting accumulated pro-cess technologies and

production technologies.

Highlights:

·

Basic, vigorous plan can deal with process

side-effects

·

Fluids, condensate, and even little particles

·

No oil or water in contact with process

·

No contact between working segments in the

packaging

·

Short gas way through the siphon for brisk

release

·

Broadened shaft for either V-belt or direct

drive

Ordinary

Applications:

·

Dissolvable Recovery

·

Fume Recovery

·

Freeze Drying

The highlights of Dry

Screw Vacuum Pump:

Protected Variable pitch rotor structure.

Water Jacket cooling of procedure gas – no inward virus

spots.

Controllable to show hot or cold as required to the

procedure application.

Basic, Smooth Rotor Profile – The Screw rotor configuration

scores over snare and paw, Tri and twin projections types, from numerous points

of view.

Rotor shaft is rough one – piece segment with more prominent

shaft quality and no dismantling issue.

Tip freedom is increasingly liberal, consequently

particulate resistance is astounding.

Gas/Vapor move through Screw is Straight, short gas/fume

travel way length, which encourages the quicker siphon down time. Dry Screw Vacuum Technology Korea

One piece, rough jacketed body, with no segments inside, for

straight exchange of gas, fluids and particles. No issue of rotor sticking

because of gathering of slug, fluids and particles, if there should arise an

occurrence of segment type body.

Doesn't allow reverse of gas or slippages in gas move and

pressure.

Naturally protected: As the release tight siphoning

component utilizes no oil or fixing liquid for vacuum age laborer presentation

to spilling process gas or debased oil is practically disposed of.

No metal to metal contact between working parts, handles

fluids, slugs and particles.

Constant activity anytime on execution bend.

Low Noise and vibration levels, Compact low-profile

structure.

Handles wet corrosive fumes and high liquefying point media.

Our group can help you in choosing a dry screw vacuum siphon

framework that will best meet your custom application needs. Get in touch with

us to examine your particular needs.

Comments

Post a Comment