SVC Diverse Applications for Dry Screw Vacuum Technology

SVC was established based on advanced technology and

management philosophy of value creation with customers and SVC is a specialized

company which manufactures the world highest level vacuum pump and vacuum

pumping system.

SVC has been designing, manufacturing and supplying

important process of Dry Screw Vacuum Pump & System, Liquid Ring Vacuum

Pump & System and Steam Ejector system and employees who have over 30 years

of vacuum experience including board of directors have been growing as a true

partnership of the various industries with grafting accumulated pro-cess

technologies and production technologies. Screw type vacuum

pump machine

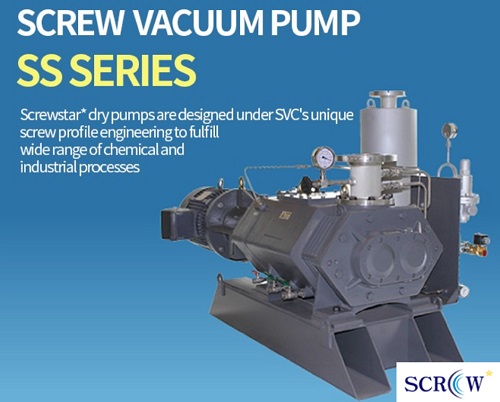

Screwstar Dry pumps are designed under SVC’s unique screw

profile engineering to fulfil wide range of chemical and industrial processes

by rotating a paired screw that efficiently admit gases from inlet into the

pump inside and compress through the screws’ swept volume toward the discharge.

The hybrid screw design with engineered combination of vari-able pitches, in

comparison with traditional ones, significantly increases compression

efficiency for faster and smoother pumping but generation for safe pumping,

particularly at the discharge, which comes from the specialty design of unique

hydrodynamic spiral Dry screw vacuum

Technology korea jacket

cooling mechanism that results fulfilling ATEX directives.

Dry screw vacuum pumps work with two screw rotors rotating

in inverse ways. This snares the medium to be pumped between the chamber and

the screw chambers and transports it to be the gas release. Vacuum is framed by

the head of suction, Compression and releasing through passing regular

intervals of two little pitches. Mixture consolidated variable pitch is a screw

type to cure the detriment of single pitch and flexible pitch contrast with

ordinary single pitch.

Screw Vacuum pumps are Rotary Vane type with great fixing

course of action. The vanes are sliding sort with spring stacked mounted at 180

separated on to a round and hollow turning part. The siphons clear the air from

siphon in take to the fumes through at exhaust port. The notoriety of this

cycle of expelling air on any gas from a framework or any vessels brings about

the production of high Vacuum. A productive oil dissemination framework gave in

the siphon serves to seal the siphon from climate just as to grease up every

single mechanical part.

Comments

Post a Comment