Everything you need to Know about Dry Screw Vacuum Pump

SVC was established based on advanced technology and

management philosophy of value creation with customers and SVC is a specialized

company which manufactures the world highest level vacuum pump and vacuum

pumping system.

SVC has been designing, manufacturing and supplying

important process of Dry Screw Vacuum Pump & System, Liquid Ring Vacuum

Pump & System and Steam Ejector system and employees who have over 30 years

of vacuum experience including board of directors have been growing as a true

partnership of the various industries with grafting accumulated pro-cess

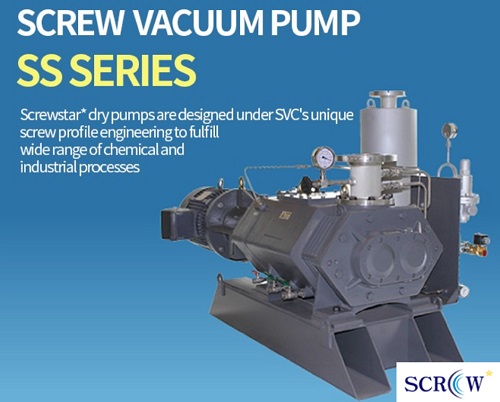

technologies and production technologies. Screw vacuum pump

Dry Screw Vacuum Pump

Dry Screw Vacuum Pump is a cross breed variable pitch screw,

dry running non-contact type vacuum Pump. Two equal screws, having an

exceptionally advanced surface profile comprising of an archimedean and quimby

bend and a curve, pivot in inverse course. Drive shaft pivot is clock savvy

(CW) when seen from the engine end (Drive end) of the Pump. Helical cut

planning gears position these screws comparative with one another. The siphoned

gas is compacted into the released port by the pivot of the screws. A

particular measure of leeway for each siphon size is kept up between the two

screws and among screws and body to keep away from any metal to metal contact.

The intensity of the engine is transmitted to the fundamental shaft through a

coupling. dry screw vacuum

pumps manufacturer

Dry screw pumps is ideally appropriate for applications in

low and medium vacuum. It is planned for modern use as well as for covering

applications. SVC’s dry is the perfect answer for all territories which require

without oil vacuum. Our screw siphons in the SVC’s Dry arrangement are perfect

for use as independent pumps. They give the inner pressure that is essential

for diminishing vitality costs in SVC’s Dry pumps. It additionally empowers

thermally delicate gases to be siphoned. The dynamic without wear seal between

the bearing and the siphon chamber increments operational dependability. The

siphon's creative plan and low speed bring about negligible weight on the

orientation and seals

Comments

Post a Comment