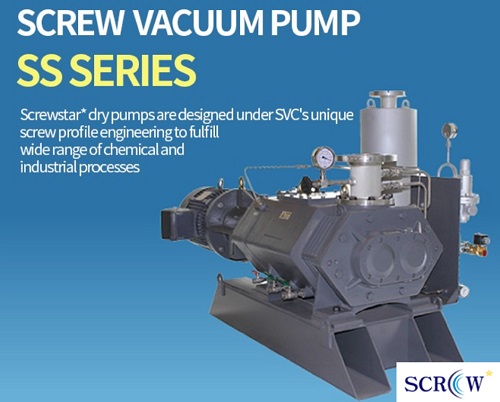

An overview of Reliable Dry Screw Vacuum Pumps by SVC

SVC was established based on advanced technology and

management philosophy of value creation with customers and SVC is a specialized

company which manufactures the world highest level vacuum pump and vacuum

pumping system.

Screwstar Dry pumps are designed under SVC’s unique screw

profile engineering to fulfil wide range of chemical and industrial processes

by rotating a paired screw that efficiently admit gases from inlet into the

pump inside and compress through the screws’ swept volume toward the discharge.

Dry Screw Vacuum Pumps

Dry vacuum pump technology– particularly factor pitch screw

substance dry pumps - offer clear, quantifiable points of interest in a wide

assortment of fundamental applications. An appropriately structured dry screw

vacuum pump guarantees the preparing needs are cultivated with a protected,

solid, and financially savvy arrangement. dry screw

vacuum pumps manufacturer

Dry screw vacuum pumps require no water or oil for fixing or

grease in the vacuum stages. Therefore, these dry vacuum frameworks dispense

with profluent age, contamination, and high treatment costs. This diminishes or

kills squander removal expenses and plants accomplish investment funds in

upkeep costs

Dry screw and fluid ring vacuum pumps are turning positive

removal siphons, yet they have contrasts. The dry vacuum pump doesn't utilize

liquids to make a vacuum, while the fluid ring does. high level vacuum

pump distributors

Dry screw pumps make a vacuum through the pivot of two screw

rotors, orchestrated in equal, turning in inverse bearings. The rotors encase

or trap the gas on the bay side and convey it to the high-pressure side or gas

release. During the pressure procedure, the rotors don't reach one another.

Therefore, there is no requirement for oil or working liquids in the pressure

chamber, which is the reason this is alluded to as "dry" innovation

Applications

Dry screw vacuum pumps convey a spotless, sans oil vacuum

for an assortment of modern applications. These frameworks perform with low

rotational speed guaranteeing smooth and strong activity. Higher release

pressure capacities alongside a high capacity to bear fume and residue ensure

more procedure time with long help life.

·

Fine and

Specialty Chemicals

·

Pharmaceuticals

·

Petrochemicals

·

Oleochemicals

·

Emerging

Applications

Comments

Post a Comment